Polyimide

Film Stiffener ( Brown/Black)

Halogen free Polyimide film stiffener is made of high heat resistant

and high adhesive adhesive coating on PI film substrate,

and the thickness is from 1mil to 10mil. The excellent properties of

heat bonded to ensure its good adhesion on copper foil

and PI material, widely used in various FPC reinforcement.,

Polyimide stiffener have been supplied to world-renowned flexible

PCB manufacturers with excellent reputations. are tested according

to IPC standards.

PI Film Thickness: 2mil~9mil (0.05mm~0.225mm)

Adhesive Thickness: 1mils (0.025mm)

Width: 250mm/roll , 500mm/roll

Length: 50m/roll , 100m/roll

Adhesive Type: Halogen free or Flame Retardant & RoHS

Release Liner: Release paper or PP film

Above products have two series: Halogen free or Flame Retardant &

RoHS series.

Application ideals

1. Traditional flex circuits

2. High density flex circuits

3. Chip on film (COF) substrate

4. Chip scale packaging (CSP)

5. Ball grid array (BGA)

6. Tape automatic bonding (TAB)

Polyimide Coverlay

Film (White)

Polyimide coverlay film is a high-performance thermosetting

converlay. After the Thermosetting Converlay is attached to

the material which needs to be protected, a pressure of 5-10 MPa is

applied by using a quick press at 170-185°C for about 30 seconds ,

then complete the operation. Structure Features The product is easy

to use, only need a quick pressure, without curing later;

Has good adhesion to metal, PET, PVC and other plastics; Has

excellent electrical insulation.

Halogen free white Polyimide Coverlay is made of polyimide film

coated high performance thermosetting epoxy resin adhesive,

release paper as isolation layer, coating on the surface of the

polyimide film with high performance white ink,

curing at high temperature to form the heat insulation film. With

excellent flexibility, yellowing resistance,

high temperature resistance, high reflection rate and other

properties. This series of products are suitable for

high grade LED products,such as car taillights, steering lights,

backlight and so on.

Whole Film Width: 250mm

PI thickness : 0.5mil/1mil (12.5um/25um)

Adhesive thickness:10--25um

Ink thickness : 8--15um

Release papers: 130um

Features:

1.The product is easy to use, only need a quick pressure, without

curing later;

2.Has good adhesion to metal, PET, PVC and other plastics;

3.Has excellent electrical insulation properties;

4.Environmental friendly, does not contain any heavy metal elements

and halogen.

Polyimide Coverlay

Film ( Yellow/Black )

Halogen free

polyimide coverlay film is a kind of high temperature thermosetting

epoxy resin coated with polyimide film.

the insulating coating is made of release paper as insulation layer

and cured by high temperature. The series

of materials are widely used in FPC manufacturing for line

protection and insulation.

Whole Film Width: 250mm

PI thickness : 0.5mil/1mil (12.5um/25um)

Adhesive thickness:15--25um

Release papers: 130um

Features:

1.Cover and protect the FPC line and enhance the rupture resistance

of FPC

2.Protect circuit not affected by temperature, humidity, pollution

or corrosive substances

3.Cover the circuit for the subsequent surface treatment of FPC

4.To resist welding in the subsequent SMT of FPC

Polyimide Bonding Sheet (Pure Adhesive Film, White)

Pure adhesive film is made of high adhesive polymer adhesive

with a thickness of 12-40um.

The adhesive film is three layers of composite structure materials,

which are protected by a protective

film and a release paper. The product is served as a complementary

product for flexible copperclad laminate ,

its functions include surface and heat insulation.

Pure adhesive film is mainly used in the FPC hot pressing,

strengthening, PI, multilayer board bonding,

FR4 substrate, soft and hard bonding plate and aluminum based metal

plate bonding.

Whole Film Width: 250mm/500mm

Length: 200m

Acrylic Ester Resin Adhesive Thickness : 12--40um

Features:

1.Suitable to traditional way and rapid pressing at the same time.

2.Good heat resistance and high peel strength for a long time.

3.Good flexure resistance, suitable for PFC-multilayer.

4.Good storage-ability for half a year at room temperature.

5.Good metal bonding and insulation.

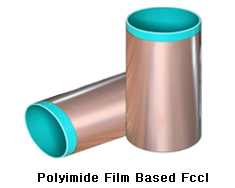

Polyimide

Film Based Fccl

(Single-side FCCL)

Epoxy resin PI film based FCCL is composed

of three kinds of materials, copper foil, adhesive and PI film,

which are compounded by high precision coating technology. With high

temperature resistance,

high insulation, high flexibility and other characteristics.

Widely used in FPC manufacturing. Type: Single-side FCCL(3 layer)

Copper Clad

Polyimide Film uses amber or black polyimide film as base film and

plated with copper foil tape.

It’s usually used together with thermosetting coverlay film on

Flexible Printed Circuits boards industry,

featuring excellent high temperature resistance and insulation

performance. The soldering resistance temperature

is 288℃ without bubbles and delamination.

Features

1. Good shear resistance

2. Soldering resistance temperature is 288℃

3. Excellent chemical stability ,

4. Radiation resistance,

5. Chemical solvent resistance and anti-corrosion

6. Easy to die-cut in any custom shape design

7. High class electrical insulation

8. Thermosetting adhesive

9. Smooth finish, no bubbles and delamination

Polyimide Film Based Fccl

(Double-side FCCL)

Epoxy resin PI film based FCCL is composed

of three kinds of materials, copper foil, adhesive and PI film,

which are compounded by high precision coating technology. With high

temperature resistance,

high insulation, high flexibility and other characteristics.

Widely used in FPC manufacturing. Type: Double-side FCCL(5 layer) .

Application:Products are mainly used in notebook computers,

monitors, mobile phone antennas, mobile phones,

printers, electronic appliances, industrial instruments,

communication equipment and other circuit.

Whole Width: 250mm

Polyimide thickness: 12.5um、25um

Adhesive thickness: 13-25um

Copper thickness:12.5um、18um、35um

Feature

Excellent high humidity and temperature resistance

Excellent dimensional stability,High flexibility and

Excellent Migration ability

Excellent electrical,chemical and thermal property

Halogen free and Flame retardancy UL 94VTM-0

Meet with IPC standards